CVD / CVI coating systems

chemical vapor deposition and gas phase infiltration

Thermally induced CVD is a powerful tool for the deposition of conformal coatings made of various dielectric, semiconducting and metallic materials, either in a monocrystalline, polycrystalline, amorphous or epitaxial state on small or large area substrates. Typical coating materials are pyrolytic Carbon, Silicon Carbide, Boron Nitride amongst others. By use of synthetic precursors the coatings are extremely pure, meeting typical requirements of the semiconductor industry. A wide range of coating thickness is possible, depending on the process parameters, from single or few atomic layers up to solid protective or functional coatings with a thickness in the range of tens of nanometers to hundreds of micrometer, up to monolithic parts with thickness up to several millimeters.

Thermally induced CVI is a CVD-related technology for the infiltration of matrix material into porous or fibrous preforms, in order to produce parts made of composite materials with enhanced mechanical properties, corrosion resistance, thermal shock resistance, and low residual stresses. Complex shapes in a wide range of size and composition can be produced. By switching the multiple gas ports the porous or fibrous preforms can be coated with multilayer interface films before the actual deposition of the matrix itself is started.

CVD Methods:

gasphasen deposition for SiC, Si3N4, BN and AlN

SiC:

CH3SiCl3 → SiC + 3HCl

Si3N4:

3SiCl4 + 4NH3 → Si3N4 + 12HCl

BN:

BCl3 + NH3 → BN + 3HCl

AlN:

AlCl3 + NH3 → AlN + 3HCl

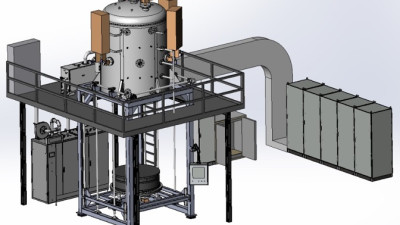

CVD systeme: chemical vapor deposition

Typ: KCE®-FCT CVD 900

Standard types CVD / CVI

| CVD Standard types |

useful dimensions (Ø/h) [mm] |

useful volume [dm3] |

max. loading capacity [kg] |

max. temperature [°C] |

max. heating power [kW] |

| CVD 30 | 360 x 295 | 30 | ≤ 25 | 1600 | 45 |

| CVD 175 | 530 x 800 | 175 | ≤ 100 | 1600 | 150 |

| CVD 900 | 900 x 1400 | 900 | ≤ 400 | 1600 | 300 |

| CVD 2500 | 1400 x 1700 | 2600 | ≤ 600 | 1600 | 500 |